Three things to consider when buying electric construction equipment

The push to “go green” is accelerating for all companies, regardless of industry. For folks in construction, increasing machinery sustainability is far more than just legally required – it’s also good for business. But what is the best strategy for adding these types of machines to your fleet? Below we list the three of the most important considerations when buying electric construction equipment.

1. Equipment Types

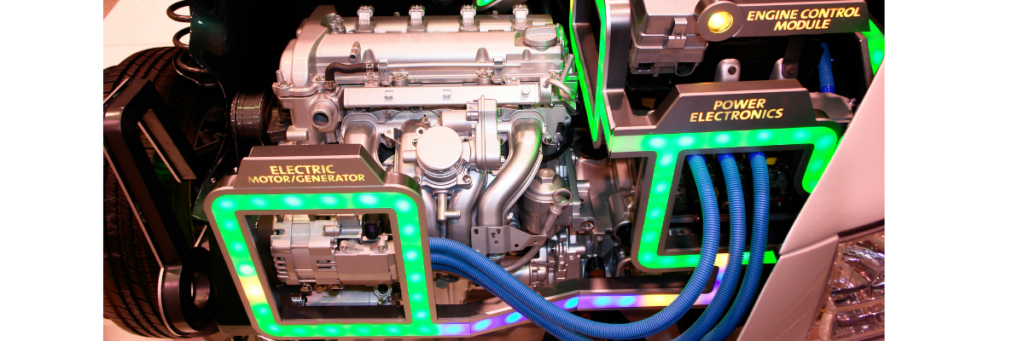

Equipment manufacturers are exploring various methods to decrease or eliminate carbon emissions. This means companies looking to purchase sustainable equipment must review their options. Electric construction equipment can refer to various machine types, including battery electric construction equipment (often known as BEVs), all-electric construction equipment, and hybrid electric construction equipment.

Here’s a quick rundown of the types of electric construction equipment currently on the market:

- Battery electric vehicles (BEVs): These machines have motors powered by electricity, typically by one or more internal batteries. Currently, BEVs are most likely to be smaller or compact construction equipment, but OEMs are finally starting to branch out to larger tonnage machines.

- Cable-powered (or “tethered”) machines: This type of electric construction equipment is powered by a cable plugged into an electrical outlet at a construction site. These machines are often found in quarries and mines.

Cable-powered machines and BEVs can also fall into the “all or fully electric construction equipment” category.

- Hybrid electric construction equipment: Machines that fall into the hybrid category use a source of electrical power, such as batteries, a power cable, or hydrogen fuel cells, combined with diesel. These versatile hybrids are helping bridge the gap between current electric construction equipment technology and future innovations that will eventually provide power density similar to diesel.

Another consideration…

- Alternative fuel-powered equipment: This category uses internal combustion engines fueled by biodiesels (such as hydrotreated vegetable oil or HVO) or biogas.

2. Environmental Impact

Understanding the environmental effects of electric construction equipment is also crucial in deciding which sustainable machines are suitable for you.

The 2022 Global Status Report for Buildings and Construction found the sector accounting for around 37% of energy and process-related CO2 emissions. Many cities and municipalities globally are adopting new rules for construction zones, including the introduction of zero emissions. Oslo, Helsinki, and Copenhagen are leading the charge in Europe, with some projects seeing contractors with zero or low-emissions equipment having a leg up over their competitors.

Rental companies, like Boels Rental, are embracing these new developments by adding electric construction equipment to their fleets. Both all-electric and hybrid electric construction equipment are available for end users to try out these types of machines.

Another great benefit of electric construction equipment is the reduction of noise pollution. While often overshadowed by discussions about sustainability, noise is a primary concern for workers at construction sites, businesses, and residences nearby. Low-noise electric construction equipment can help reduce dangerous levels of noise that can cause hearing loss, tinnitus, and even on-site accidents.

Additionally, with low emissions construction sites often including regulations on noise, electric construction equipment is an excellent solution to meet both requirements. Earlier in June 2023, Volvo Construction Equipment launched three electric construction equipment (ECE) items in Singapore. The ECEs are both zero emission and zero noise pollution.

3. Costs

Fuel, repairs, TCO. These topics are top-of-mind when choosing the right type of machine. For electric construction equipment, it’s essential to understand the associated costs and how they fit into your budget.

Electric construction equipment is currently priced above diesel machines, primarily due to costs associated with the battery packs needed to power these assets. The bump in pricing also takes into account the time and investment in designing this type of equipment. Some studies have shown, however, that savings from forgoing diesel and reduced maintenance costs could offset the initial increased cost.

Of course, there are many more factors to consider. Two additional considerations are sufficient infrastructure for obtaining electricity and recharging times. Like electric passenger vehicles, building and maintaining the infrastructure for electric construction equipment is an ongoing challenge for the EU.

Like this article?

Click here and subscribe to our blog.

Meanwhile, OEMs like Volvo have developed machines that use lithium-ion batteries that can be charged using a 220/240-volt electrical socket. Manufacturers are also looking into options like mobile power banks and solar arrays that could provide power when the local electrical grid isn’t accessible. To help address current infrastructure challenges, companies have invested in quickly charging batteries that can last an entire workday. Volvo, Bobcat, JCB, Caterpillar, and other OEMs have released equipment with batteries that can hold a charge for 6-8 hours a day and can be recharged within 2-4 hours.

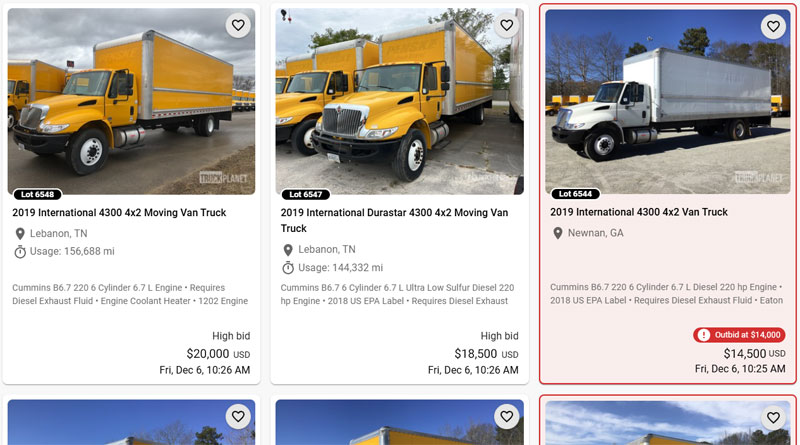

Extra: The resale value of used electric construction machinery

One last thing to consider is residual and resale values. Electric construction equipment is still developing, and most machines in the market are still running on conventional diesel. Also, most used electric construction equipment is currently in use in its first lifecycle and is not yet part of the used equipment market. More electric equipment transaction data will be collected through Ritchie Bros. over the coming years.

Another thing to keep in mind is machine operating time. With electric construction equipment, there’s no idle time. When the operator stops working with the machine, the electric engine shuts off, dramatically reducing operating time.

So, what’s the moral of the story? Regulations are becoming increasingly strict as the EU has adopted Stage V emissions standards. In a recent interview with Ritchie Bros., Riccardo Viaggi, Secretary General of the Committee for European Construction Equipment (CECE), said that electromobility is being mostly driven by market demand, often to enable compliance with local environmental regulations. And observers speculate that by 2029, most construction, mining, and agriculture equipment will be electric. When you’re ready to start adding electric construction equipment to your fleet, great options are available to meet your needs, whether BEVs or hybrid electric construction equipment. It’s an exciting time for the market, and electric equipment is here to stay.

|

Exciting new features: Watchlist Carousel and real-time Timed Auction info |